Unique application areas and main uses of peristaltic pumps

In intelligent sweeping robots, micro-peristaltic pumps are used to control the delivery of cleaning fluid or washing fluid to help the robot achieve efficient and accurate cleaning.

In high-end water dispensers, micro-peristaltic pumps can be used to control water delivery to ensure accurate and stable water flow.

In the hand washing machine, a micro peristaltic pump is used to add quantitative hand sanitizer to provide a safe and convenient hand washing experience.

In makeup machines, micro-peristaltic pumps are used to control the delivery and application of cosmetics, helping users achieve even, natural makeup.

In the fragrance machine, a micro peristaltic pump is used to control the delivery of fragrance liquid and release pleasant aroma.

In addition, micro peristaltic pumps are also widely used in other fields, such as pharmaceuticals, food processing, ceramic industry, mining, etc.

A peristaltic pump consists of three parts: driver, pump head and hose. It uses rollers or hoses to sequentially squeeze the elastic pipeline to generate peristalsis, thereby continuously transporting fluid. Therefore, peristaltic pumps operate continuously.

Why can’t micro peristaltic pumps run continuously?

When the micro peristaltic pump is continuously running, the pump tube will be continuously squeezed, and it is easy to age, lose elasticity or be damaged, thus affecting the normal operation of the pump.

Therefore, in order to protect the pump tube and ensure the normal operation of the pump, continuous operation of micro peristaltic pumps is usually not recommended.

Technical Specification

| Voltage |

DC12V |

Mode |

DRB130A-01 |

| Power |

2.4W |

Suction Value |

-20Kpa |

| Flow |

32-48LPM |

Noise |

60dB |

| Life test |

500 hours |

Product use |

Smart sweeper,hgih end water dispenser,handwash machine,cosmetics machine,fragrance machine |

What effects does the continuous operation of a micro peristaltic pump have on the pump tube?

The continuous operation of the micro peristaltic pump mainly affects the pump tube in the following aspects:

1. The pump tube will be continuously squeezed, which may cause its elastic fatigue or damage.

2. Due to the pulsating flow, the continuous operation of the micro peristaltic pump may cause fluctuations in pressure and flow in the pipeline, which may cause additional pressure on the pump tube.

3. When transporting fluids with high viscosity, high concentration or containing particulate matter, the pump tube is more likely to suffer from unstable flow, insufficient pump pressure, etc., which may cause damage to the pump tube or affect its service life.

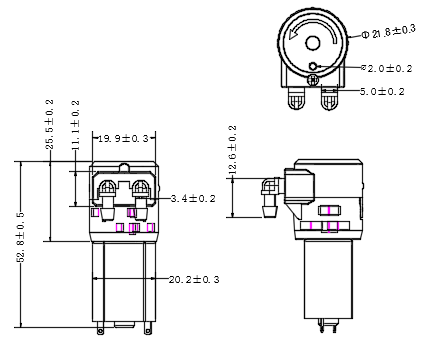

Dimension Drawing

Can the micro peristaltic pump be reversed?

Whether a microperistaltic pump can be reversed depends on its design and functionality.

If the design of the microperistaltic pump allows the motor to reverse, then the pump itself can also reverse. In addition, in order to achieve more precise flow control, some intelligent peristaltic pumps may also have

Be prepared to stop the self-priming function. At the moment of stopping, in order to make the flow rate more accurate, the pump body will suck back, which requires the motor to reverse rotation.

How is the reversal of the micro peristaltic pump achieved?

Whether a microperistaltic pump can be reversed depends on its design and functionality.

If the design of the peristaltic dosing pump allows the motor to reverse, then the pump itself can also reverse. In addition, in order to achieve more precise flow control, some intelligent peristaltic pumps may also have

be prepared to stop the self-priming function. At the moment of stopping, in order to make the flow rate more accurate, the pump body will suck back, which requires the motor to reverse rotation.